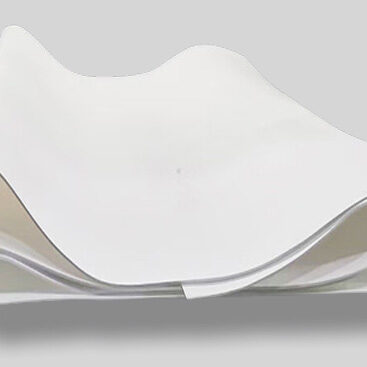

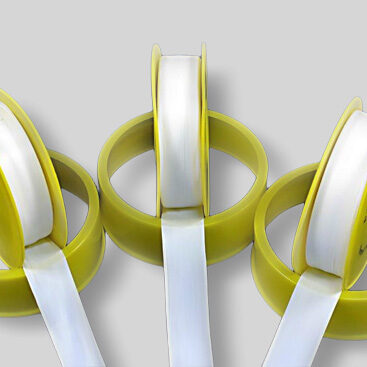

Expanded PTFE gasket sheet is made of 100% expanded P.T.F.E. by using special process that produces a uniform and highly fibrillated microstructure with a great lot of fibers running in multidirection. These create a soft and pliable, yet very tough gasket that has excellent resistance of pressing, creep relaxation and cold flow.

Expanded PTFE sheet possesses universal resistance against common chemicals, except melted alkali metal, fluorine at liquid and gas states. It can be stored without any time limits and can seal uneven and damaged flanges

– full chemical resistance like solid sintered PTFE

– resistance against acids and bases of pH 0 to 14

– UV-resistant

– no aging, unlimited shelf life

– nontoxic, biologically inert

– non flammable

Industries used: chemical, petrochemical, oil refining, chlor-alkali, acid making, phosphate fertilizer, pharmaceutical, pesticide, chemical fiber, dyeing, coking, gas, organic synthesis, non-ferrous smelting, iron and steel, atomic energy and high-purity product production (such as ion membrane electrolysis), viscous material transportation and operation, food, beverage and other processing and production departments with highly stringent health requirements.

It is suitable for all kinds of fluids, strong acids, alkali, gases, solvents, hydrocarbons, water, chlorine gas, aluminum fluoride, hydrogen oxide, etc. under harsh working conditions of sealing, and has good performance in petrochemical, caustic soda, chlor-alkali, shipbuilding and other industries.

Use equipment: pipes, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, chillers and other flange joints sealing parts, especially suitable for complex geometry, flange surface uneven, glass enamel and other special flange sealing.

Performance characteristics of expanded PTFE gasket:

1, easy to cut, easy to install

Gaskets that can be mechanically stamped or cut by hand into any shape make your job easier.

2. Suitable for rough surface sealing

The ZD-G1630 expanded polytetrafluoroethylene gasket has a unique ability to adapt to forming, and can produce a good sealing effect on rough or damaged flanges without adding much pressure.

3. Strong chemical corrosion resistance

In addition to melting alkali metal, free fluorine, tertiary nuclear and other very few chemical substances do not react with any chemical substances, in the temperature (315 ° C) allowed range of all sealing occasions can be applied, which will greatly reduce the variety and number of seals.

4. Good creep resistance and cold flow resistance

The unique high density fiber structure makes it have strong creep resistance. Because it does not contain any adhesives and additives, its mechanical properties are very stable